Living materials could grow products

- Published

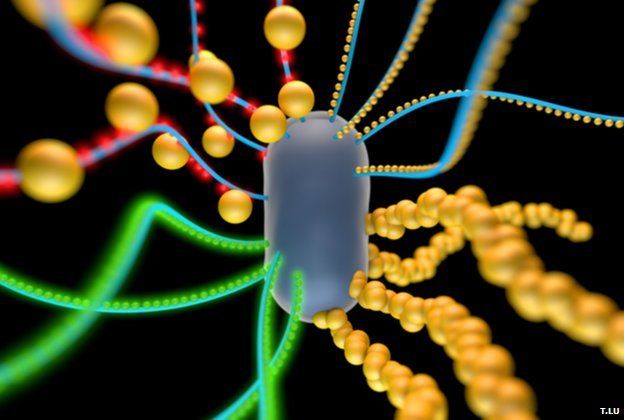

Living materials based on bacteria and grown in a Boston lab could point to a greener way of manufacturing.

In future, complex and interactive structures could be grown using cells programmed to assemble into intricate patterns, the researchers argue.

They describe patterned biofilms made from proteins tougher than steel, designed to incorporate semiconducting crystals and electrical wiring.

Their research is published in Nature Materials.

The living biofilms are the creation of synthetic biologist Timothy Lu and his team at the Massachusetts Institute of Technology.

They are a marriage of advanced techniques in genetic engineering, which reprogramme a cell's function, and the kind of protein chemistry that underlies the biofilm gloss we find on our teeth.

"Our vision is to create living materials, in which living cells grow, lay down biopolymers and control the inorganic compounds around them," Professor Lu explained.

"Just imagine what we could achieve if we could grow physical devices and structures from bottom up using cells and minimal inputs, rather than manufacture and shape them from top down."

Zebra stripes

It is, of course, the kind of engineering nature has been doing for more than three billion years.

Bone growth, for example, starts with cells that arrange themselves into complex patterns, and excrete specially adapted proteins which template the strong, white calcium phosphate structures we see.

The new work builds on developments in protein engineering, where complex, functional biopolymers self-assemble to make scaffolds onto which other crystals can be templated.

What is different is that the proteins in this instance are produced by cells that have been reprogrammed using synthetic biology techniques developed by Timothy Lu and others at MIT, Harvard and Boston Universities.

These techniques are based on the understanding that some genes work like components of electronic circuits - switches, for example, that can turn on or off other parts of the genome.

Prof Lu's group is one of several that have developed living biological computer circuits this way. Other researchers have programmed cells so that they grow into complex patterns, like zebra stripes.

Electrical switch

The new work brings these trends together, creating genetic switches that respond to chemical signals, and engineered genes that produce synthetic filaments of a protein called curli - biopolymers already known to have the strength of steel.

As a result, bacteria secrete the protein matrix under instruction from stimulants added by the researchers, or broadcast by neighbouring cells.

The team has also adapted the proteins so that inorganic materials can grow on them - such as quantum dots which respond to light, or metals to make conducting wires.

In one experiment, they programmed bacteria to grow an electrical switch, either opening or closing an electrical circuit according to the chemical stimulus applied.

"This is only a beginning," said Prof Lu. "We've shown that even with simple modifications we can get some pretty interesting materials. Downstream we'd like to try more sophisticated designs."

Synthetic biologist Lingchong You, from Duke University, agreed the new work was a remarkable step forward.

"In theory you can put a number of protein-expressing genes under the control of elaborate self-organising genetic circuits. Once you have that, every cell could carry the blueprint of the design you want to make," he said.

Professor You envisages smart biofilms that not only scavenge and clean up the pollutant cadmium at solar-cell factories, but then grow integrate the metal into cadmium-selenide crystallites that would themselves be used in photovoltaic devices.

At MIT, Timothy Lu's team is working on a living glue that can work underwater like the adhesives of barnacles.

Cells engineered to produce the right combination of proteins to attach firmly to surfaces would also incorporate control elements to turn the process on or off, perhaps in response to light signals.

"We'd also like to include stress-responsive circuits, so that the cells would make more glue if the join is stretched or broken," added Dr Lu. "That way we'd have materials that self heal, the way wood can."

Best suited to high-value materials ("we won't be making the world's bricks this way," Dr Lu confessed), the synthetic biological approach would run at room temperature, avoiding the high energies and harsh chemicals used in today's manufacturing processes, the researchers said.